Acid Esterification

FEEDSTOCK PRETREATMENT – HIGH FFA PRETREATMENT

ACID ESTERIFICATION – HIGH FFA PRETREATMENT

PATENT PENDING TECHNOLOGY

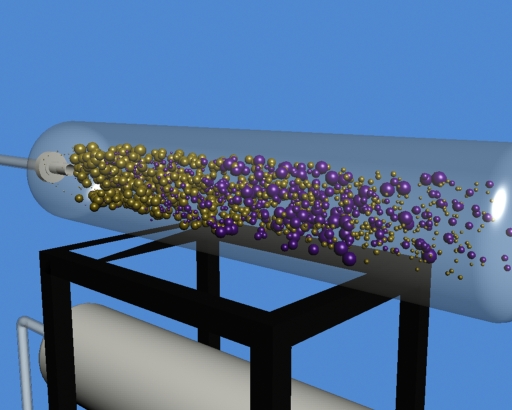

The FSP System:

Readily available, less expensive feedstocks contain a significant amount of Free Fatty Acids (FFA). These FFA’s must be removed prior to the transesterification process, as they will form soap through an alkali catalyst during transesterification. Traditionally, FFA found in biodiesel feedstocks is converted into Fatty Acid Methyl Ester (FAME) through Esterification with Methanol and using Sulfuric Acid (H2O4) as a catalyst. Reaching >2% FFA is easily achieved through Acid Esterification. SRS’ FSP System for Acid Esterification pretreatment enables new and existing plants the ability to incorporate multiple high FFA feedstocks.

Key advantages of the FSP-Series Pretreatment System:

- Low yield loss

- Prevents soap formation

- Scalable from 2.5% FFA or higher, sized from 100,000 – 150 MMGY

- Energy efficient

- Quick return on investment

- Mitigates risk for high FFA feedstock environment

During the FSP System Feedstock Pretreatment / Esterification Process:

- Methanol and acid are mixed and injected into the oil stream

- Mixture is heated and reacted under pressure and temperature

- After Esterification, the modified waste additive is added and mixed with oil-methanol stream while cooling

- Light layer and heavy layers are separated with a special designed separator

- The light layers will contain the FFA and are treated to convert to usable oils

- The methanol is recycled

- The usable oils are centrifuged and ready for transesterification