Esterification

FEEDSTOCK PRETREATMENT – HIGH FFA PRETREATMENT

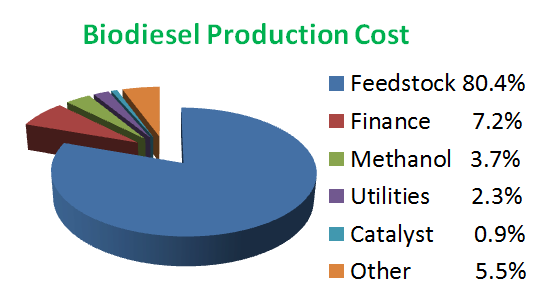

With the price and availability of feedstocks in today’s market having your plant be multi-feedstock capable is not only a competitive advantage – it’s a business necessity. If you have a plant designed to use only refined oils, adding High Free Fatty Acid (FFA) Pretreatment opens up a world of new feedstock opportunities. Whether it be animal-fat based feedstocks such as beef tallow or chicken fats, or one of the new emerging feedstocks such as Algae-oil or Jatropha, they all share one thing in common; these readily available, less expensive, feedstocks all contain a significant amount of FFA, amounts too high for base transesterification.

Esterification increases the yield of biodiesel. When oil feedstocks contain an excess of free fatty acids they have to go through the process of esterification. The key to effectively preparing for the esterification process is to make sure the feedstocks have been sufficiently filtered by removing all contaminants and water. Upon filtration the feedstocks are fed to the acid or resin esterification process. The catalyst, sulfuric acid, is dissolved in methanol and then mixed with the pretreated oil. Once the mixture is heated and stirred, the free fatty acids are converted to biodiesel. The final step of esterification is to dewater and feed the product to the transesterification process.

SRS International offers two different Esterification technologies that are scalable, continuous-flow, skid-mounted systems which can front-end any existing biodiesel system, efficiently converting FFA into useable oil with no yield loss.

Whether you’re equipping your existing plant to handle lower cost feedstocks, or planning a turnkey refinery with feedstock flexibility, SRS’ Pretreatment technologies will make your biodiesel plant multi-feedstock ready.

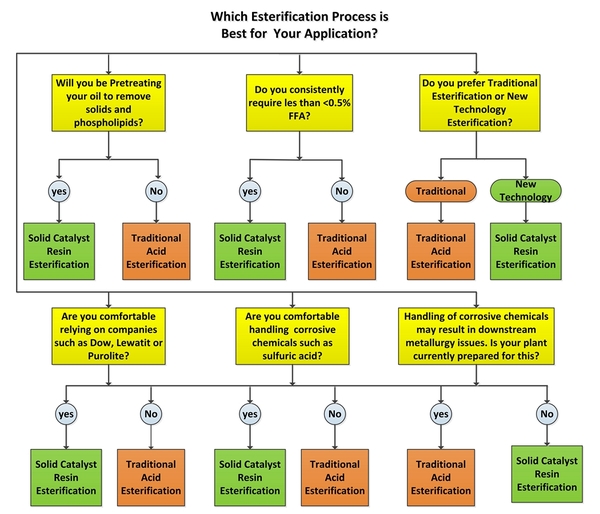

Need help deciding which Esterification Method is best for you?