Biodiesel Washing

SRS employs a resin based biodiesel washing and polishing system for a variety of different applications. Biodiesel washing utilizes resin beds in the final stage of the biodiesel production process to polish the biodiesel and remove impurities such as free glycerol, soaps, waxes, moistures and salts from phase-separated methanol-stripped biodiesel without increasing the biodiesel’s acid number. These Hydrogen Bonding Adsorber Resins do so without having to utilize costly water wash or once use filtration systems. The resins do not degrade after each use, allowing for continual reuse.Hydrogen Bonding Adsorber Resins allow a biodiesel plant to produce high quality fuels at a lower cost because resins are regenerable, easy to use, and require very little maintenance. The average lifespan of resins is approximately 5 years. For the most part, the efficiency and life span of resins primarily depends on how well the biodiesel and glycerin were separated in the first phase. The resin step is meant for polishing and removing impurities only and should not be viewed as a replacement for the glycerin/biodiesel separation process.

SRS’ HYDROGEN BONDING ADSORBER RESIN BEDS

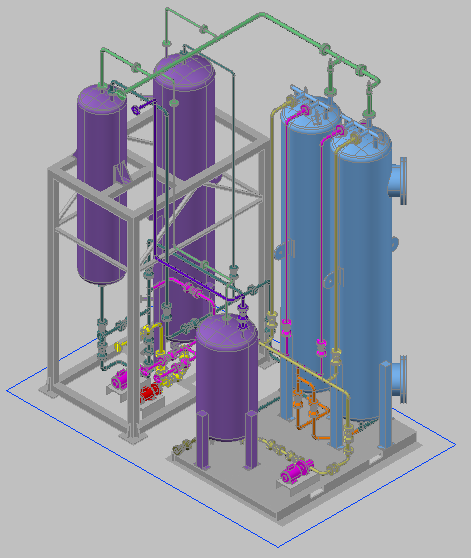

SRS employs a lead-lag type of two column configuration (see photos below). This type of system allows for continuous plant operation with little to no down time while resin regeneration is taking place. A two column type system allows for one column to be in regeneration mode while the other column remains in commission and operable.

The resin regenerating process is fairly simple and takes place periodically in order to wash the resins clean of captured impurities. This method utilizes methanol to regenerate the resins in one bed while the other resin bed remains operable.

Photos of resin beds at biodiesel plant in Moberly, Missouri

Need More Help ?

Contact Us