Solid Catalyst Esterification

FEEDSTOCK PRETREATMENT – HIGH FFA PRETREATMENT

SOLID CATALYST RESTIN ESTERIFICATION – HIGH FFA PRETREATMENT

PATENT PENDING TECHNOLOGY

The ESTFS System :

Realizing the importance of feedstock costs, permitting issues with acids and chemicals, yield losses and stringent ASTM D56751-12 and EN 14214 standards, we have a solid based heterogeneous (Resin) Esterification technology designed to minimize the overall costs of equipment, eases the complexity of operations and can be used for up to 100% FFA from multi-feedstocks such as trap grease, brown grease, waste vegetable oil, yellow grease, tallow, poultry fat, choice white grease, pork fat, algae oil, soybean oil, corn oil, Jatropha oil, camelina oil, rapeseed oil, moringa oil, pongamia oil, sunflower oil, crude palm oil, palm kernel oil, palm fatty acid distillate, palm sludge oil, and coconut oil.

Key Advantages of Resin Esterification :

- Lowers costs associated with feedstock by allowing up to 100% FFA based feedstock’s

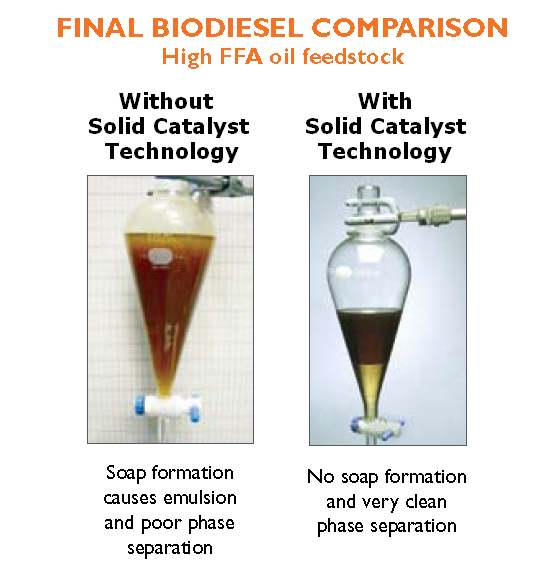

- SRS’ Solid Catalyst Technology converts feedstock with any FFA content to achieve <0.1% FFA

- Accepts up to 99.9% FFA converted into biodiesel, not soap

- No sulfur or other metals added

- Simple and safe process

- Is the fastest solid esterification catalyst

- SRS’ solid catalyst technology is fully compatible with all standard transesterification processes

- Increases your throughput by adoptin the most productive esterification catalyst in the industry

- Effective removal of both physical and chemical foulants: cations, proteins, phospholipids

- Is a skid-mounted, space-efficient unit

- Single-point connections for all feeds and utilities

- Utilizes a two stage or three stages

- Outperforms all standard esterification catalysts, even sulfuric acid

- Extended lifetime of catalyst with the proper treatment

SRS’ ESTFS System is an Esterification process with 90% conversion in each stage. Our adjustable system configuration provides optimum output for minimum costs while using any feedstocks with up to 100% FFA. A single stage reaction is enough to reduce FFA Levels as low as 0.1% in feedstocks containing low FFA levels, while a two or three stage would cover any feedstock up to 100% FFA.

Vital Process Advantages :

- Can reduce downstream equipment fouling

- Improved biodiesel and glycerin stream quality

- Helps prevent potential side reactions caused by unwanted components

- Scalable with flow rates from 100,000 to 150 million gallons

- Feedstock flexibility which allow you to adjust to changing market conditions

- Increases your biodiesel yield

- Improve you biodiesel purity

- Reduces the overall costs of equipment

- Significantly reduces sodium methylate usage in the Transesterification process.

- Eliminates issues of handling and permitting associated with chemicals, acids and waste disposal

- Eases complexity of operations

SRS’ ESTFS System is an Esterification process with 90% conversion in each stage. Our adjustable system configuration provides optimum output for minimum costs while using any feedstocks with up to 100% FFA. A single stage reaction is enough to reduce FFA Levels as low as 0.1% in feedstocks containing low FFA levels, while a two or three stage would cover any feedstock up to 100% FFA.

Vital Process Advantages :

- Can reduce downstream equipment fouling

- Improved biodiesel and glycerin stream quality

- Helps prevent potential side reactions caused by unwanted components

- Scalable with flow rates from 100,000 to 150 million gallons

- Feedstock flexibility which allow you to adjust to changing market conditions

- Increases your biodiesel yield

- Improve you biodiesel purity

- Reduces the overall costs of equipment

- Significantly reduces sodium methylate usage in the Transesterification process.

- Eliminates issues of handling and permitting associated with chemicals, acids and waste disposal

- Eases complexity of operations

Guard Bed:

Dried and cleaned feedstock passes through the two stage, two column Guard Bed. This lead-lag configuration will filter out any remaining trace elements or components such as gums and metals which will poison the Esterification catalyst.

Why Use Guard Beds?

- Supplements or may replace conventional degumming processes

- Extends the life of the esterification catalyst

- Improves operability of downstream manufacturing processes by removing troublesome foulants

- Removes foulants that contribute to the failure of ASTM and EN Biodiesel quality specifications

- Low Capital Investment for purification of your high free fatty acid feedstock

- High capacity for foulant removal per volume and cost of purification media

- Extends the lifetime of the esterification catalyst

- High operability – responsive to variability in foulants and foulant levels

- Mechanism for foulant removal is theoretically equivalent to catalyst

- Utilizes an aging mechanism

Call one or our biodiesel specialists today to find out how to make your plant multi-feedstock capable (800)497-5841