Electrical Engineering Services-Excludes California

- Process Designing

- PFD & P&ID

- Mass & Energy Balance

- Plant GA Layout

- Design basis finalization Detail Engineering

- Distillation Column Simulation

- Heat Duty Calculation

- Heat Exchanger Design

- Pump Data Sheet

- Pump NPSH Calculations

- Equipment Data Sheet

- Piping Class Specification & Line Sizing

- Finalization of PFD and P&ID

- Line List for P&ID

- Instrument Tag No. List for P&ID

- Control Philosophy

- Bought-out Item and Instrument Data Sheet

- Interconnecting Piping Drawing

- Skid 3D Drawing

- Plant 3D & Piping Modeling

- Piping Layout and Isometric Skid

- Foundation Drawing and Load Data Drawing

- Concrete Details, Pipe rack Design, & Fabrication Drawings

- Detailed Plant Layout Drawings

- Plant Elevation Layout Drawings

- Process Plant Layout

- RFQ and Inspection

- Boiler RFQ and Order Finalization

- Pumps & Motor RFQ and Order Finalization

- Other Utility Systems RFQ and Order Finalization

- Chiller / Cooling Tower RFQ and Order Finalization

- Troubleshooting

- Root Causes and Precautionary Measures

- Necessary Action Plan

- Parent Plant Constructional Training

- Online Training Program

- Constructional Reasoning and Necessity

- Actual Start-up

- Manpower Distribution and Role Assignment

- PLC and Process Control Training

- Operational Startup Training and Operational Troubleshooting

- Preventative Maintenance Schedule and HMI Life Screens

- Support on Troubleshooting

- Completion and Overview of Training

- Testing / Pre-Commissioning

- Commissioning Activities and Handover

- Single Line Electrical Diagrams

- Schematic Diagrams (Ex: motor controls)

- Utilities schedule

- Electrical Power Supplies Data Sheets

- I/O List

- Motor Data Sheets

- Block Wiring Schematic

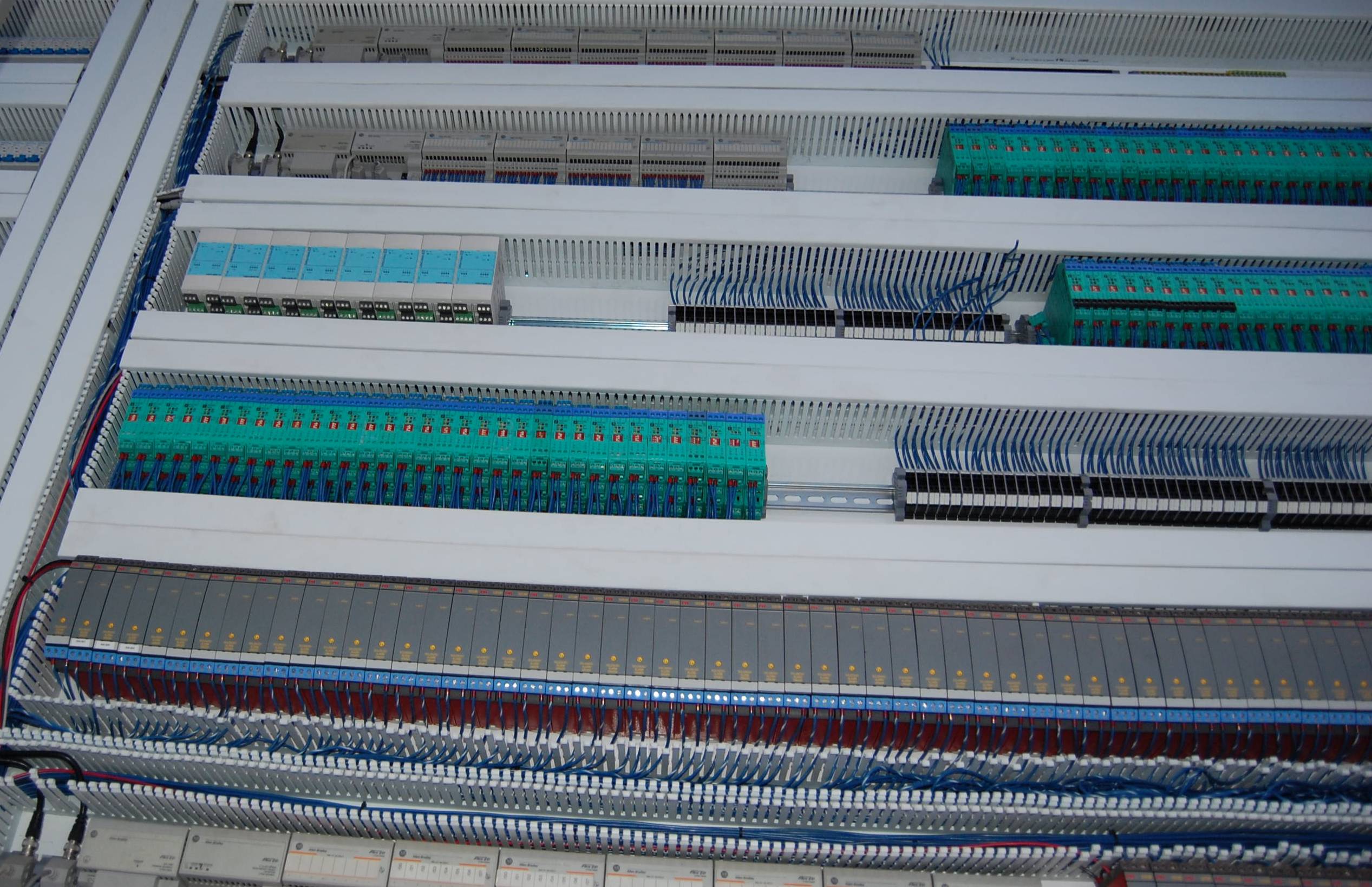

- Control Panel Details

- Instrument-Electrical-Telecoms Panel Details

- Termination Diagrams

- Cable List

- Instrument Loop Diagrams

- Data Communication Networks

- Parts List

Please call us at 800-497-5841 begin_of_the_skype_highlighting 800-497-5841 FREE end_of_the_skype_highlighting or email us at sales@srsintl.com to get information and pricing

Need More Help ?

Contact Us